Battery Switching Capacitor

65,00 €

incl. 19% VAT plus shipping

Scope of Delivery:

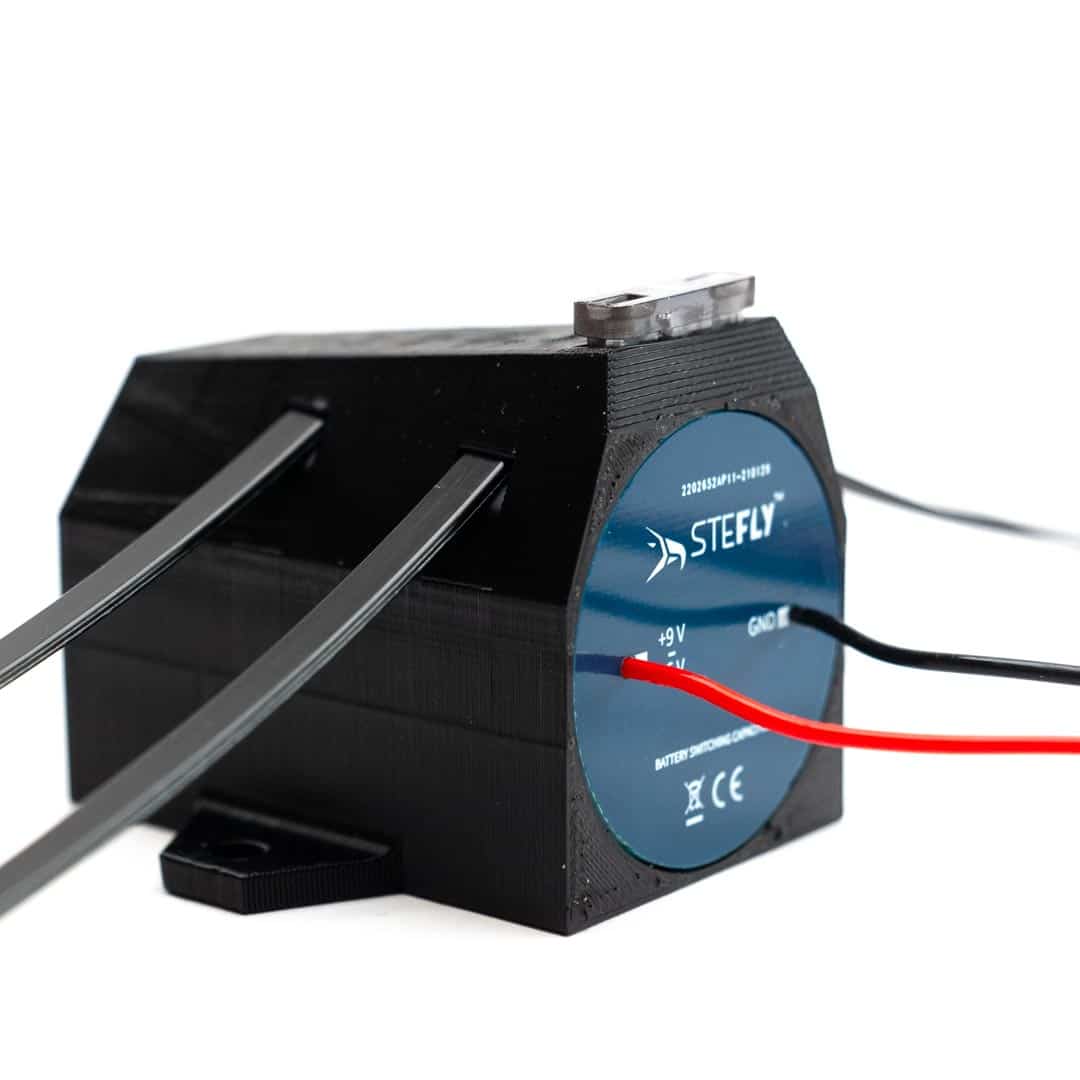

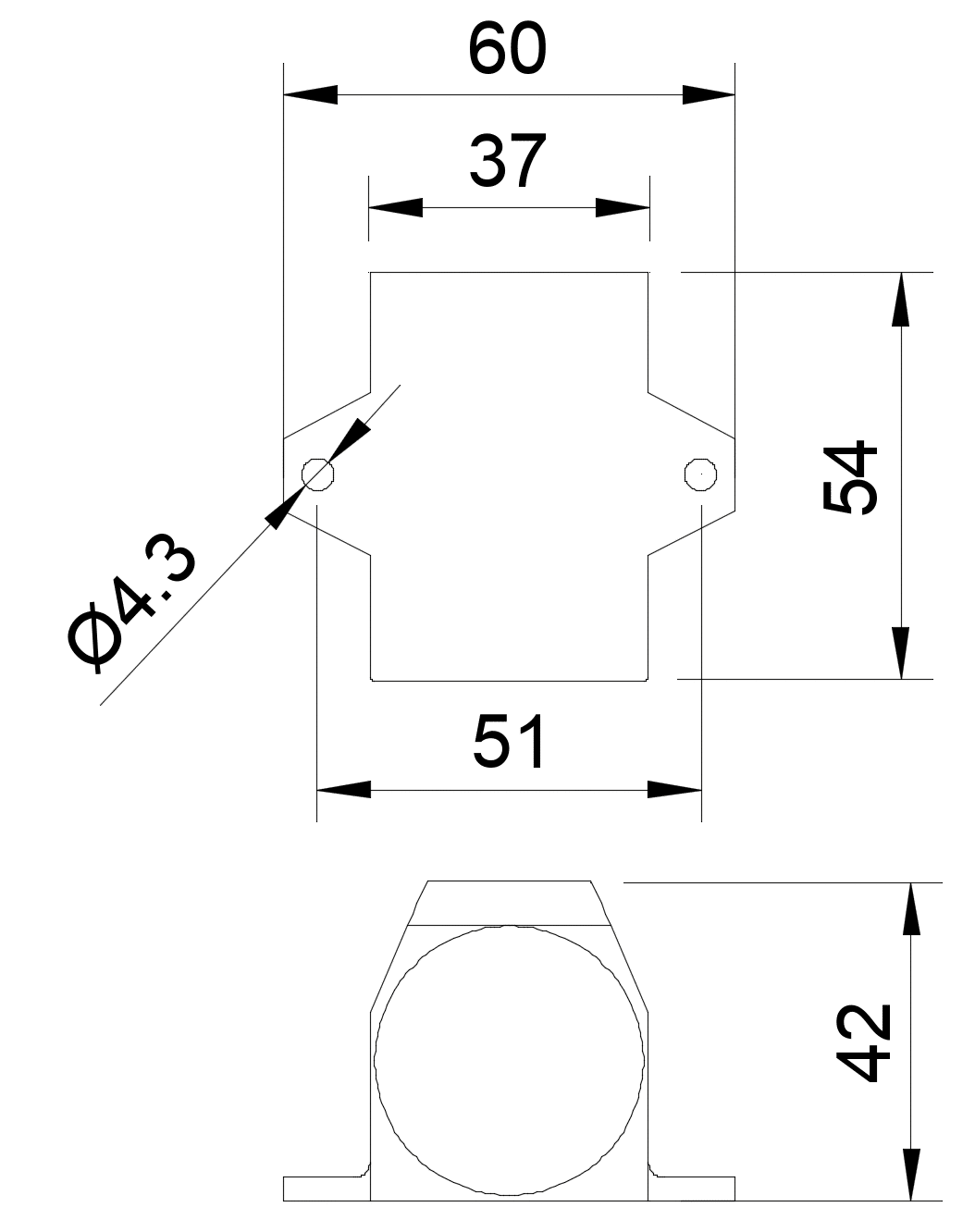

- capacitor in practical housing (allows attachment with M4 screws or cable ties) with integrated charge and discharge electronics

- reverse polarity protection and overload protection with replaceable automotive blade fuse

- 0.4 m connection wires for + and –

- 2 cable ties

Delivery time: 3 business days

- SteFly Battery Switching Capacitor :

This capacitor was designed to provide the electrical system of a glider when switching from one battery to another. The 47000 µF capacitor is equipped with intelligent electronics and encased by a functional housing. Thanks to the replaceable automotive blade fuse, our capacitor only requires one red wire for plus and one black wire for minus pole. This standard automotive blade fuse reliably protects the capacitor from irreversible damage in the event of reverse polarity (incorrect installation). The PETG housing allows flexible mounting with two M4 screws or alternatively with cable ties.

Technical Data

- capacity: 47000 µF

- operating voltage: 0 - 16 V DC

- short-term peak current during switching: 6 A

- consumption when charged (12 V): approx. 3 mA

- weight: 90 g

- maximum switching time (voltage drop from 14.0 V to 9.0 V, amperage of the avionics 0.3 A): 950 ms

- reverse polarity protection / overload protection: replaceable vehicle blade fuse (1 A or 2 A)

Installation

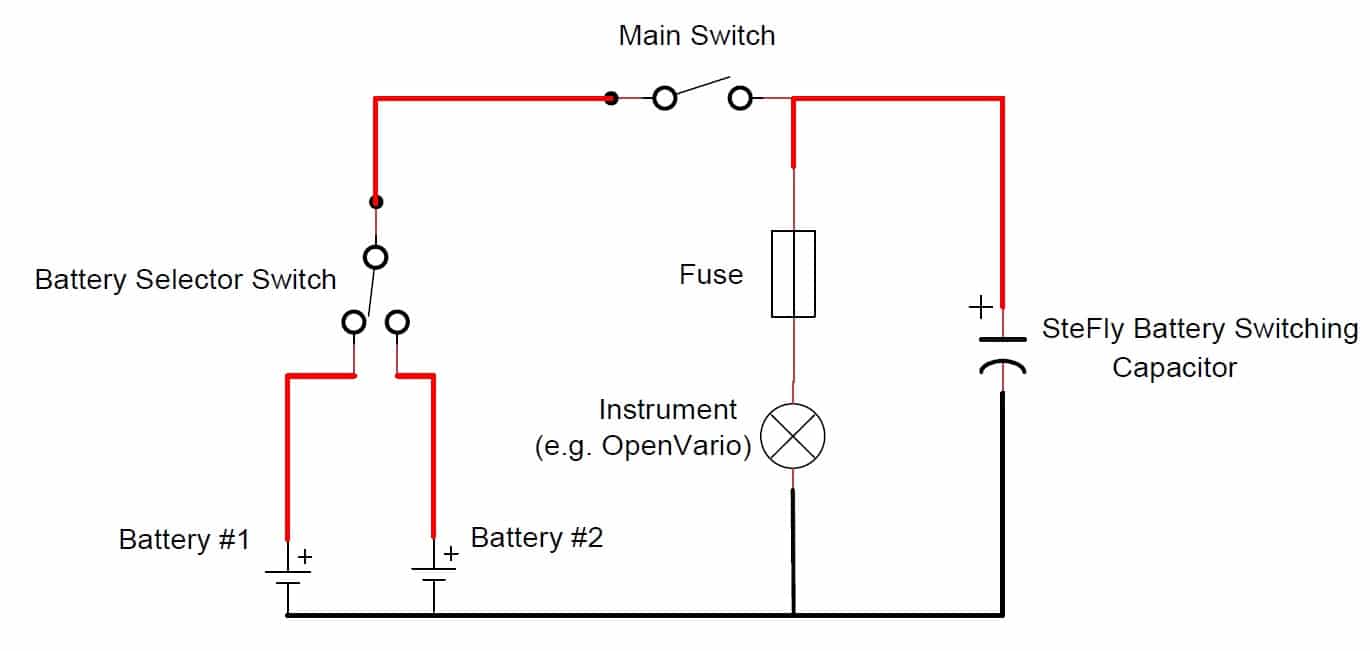

- The "Battery Switching Capacitor" has only two connection wires. The black negative cable is connected to ground, the red positive cable is connected to the positive on-board power supply (+12 V), which leads from the main switch to the avionics. The capacitor is thus integrated into the on-board electrical system in parallel with the other electric devices.

- reverse polarity protection: if the connection wires are mistakenly mixed up, the safety fuse will trigger and reliably prevent the capacitor from being damaged. The automotive blade fuse can be easily replaced after the "Battery Switching Capacitor" has been correctly connected.

Mode of Operation

- charging process: the capacitor slowly charges up with electrical energy after the on-board main switch is switched on. The peak current, that would occur with a capacitor without electronics, is limited to approx. 0.1 A. This relieves the batteries and increases their service life. After approx. 5 seconds the capacitor is sufficiently charged for a normal switching process, after approx. 10 seconds the capacitor is already 80% charged.

- discharging process: if you now switch from an empty battery (Bat 1) to a charged battery (Bat 2), the capacitor is being discharged and supplies the avionics with power. When the changeover switch finally sets Bat 2 active, then the capacitor will be recharged automatically.

- stabilization of the on-board electrical system: e.g. in the event that an additional consumer (electric bug wipers, retract a main gear electrically) leads to a high power consumption for a short time (inductive loads).

Uninterruptible power supply in gliders

Gliders usually have at least two batteries on board, allowing the avionics to be powered continuously even over a long day of flying. Particular attention must be paid to an uninterruptible power supply when switching from an empty battery to a full battery. Two systems have been established to prevent the avionics from shut down during the switching process:

- uninterruptible switch: this special toggle switch temporarily switches the batteries in parallel during the switchover process. The disadvantage is that a high compensating current flows from the battery with the higher voltage to the empty battery for a short time, which can have a negative effect on the battery life. In addition, these special switches are only suitable if two batteries are part of the on-board system.

- capacitor: a capacitor stores electrical energy, which is released again during the switching process and thus supplies the entire avionics. A shut down of the devices in the cockpit is being prevented, the data e.g. of the IGC files are recorded continuously. Another advantage is that more than two batteries can be integrated into the on-board system, while maximum two batteries are usually possible with uninterruptible switches. Thanks to the intelligent inrush current limiter of the SteFly Battery Switching Capacitor , two problems that would otherwise occur are prevented:

- very high charging currents, which in turn would have a negative effect on battery life. The integrated electronics of the SteFly system, limit the charging current to approx. 0.1 A.

- Reverse polarity leads to overheating of the capacitor (risk of explosion in extreme cases). For this reason, our capacitor has a built-in automotive safety fuse that triggers if the polarity is reversed and can be replaced as soon as the capacitor has been correctly connected. Compared to self-resetting fuses, automotive blade fuses have a lower voltage drop. As a result, the SteFly capacitor stores a maximum of electrical energy.