OpenVario Montage

Was ist im OpenVario Bausatz enthalten?

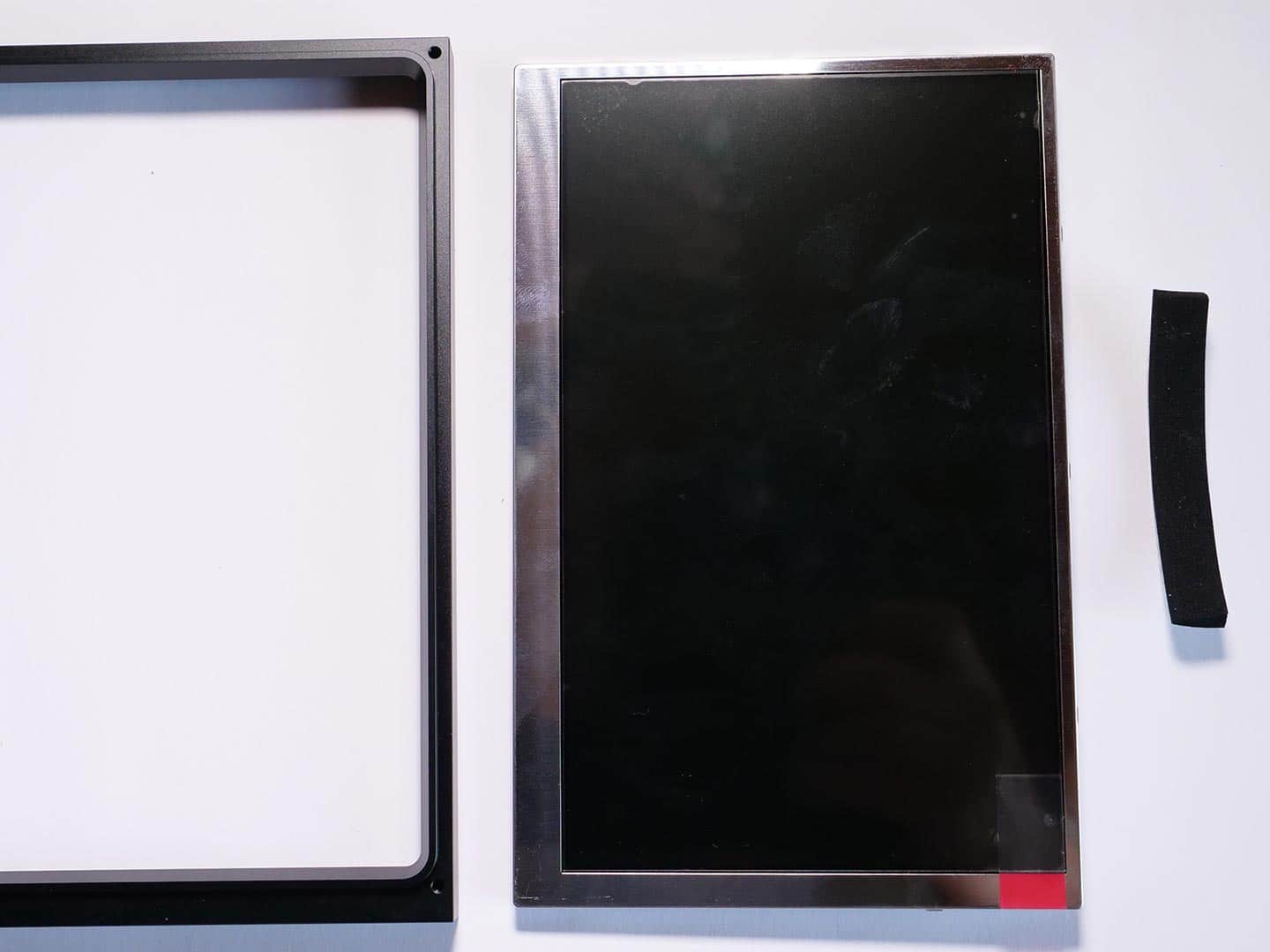

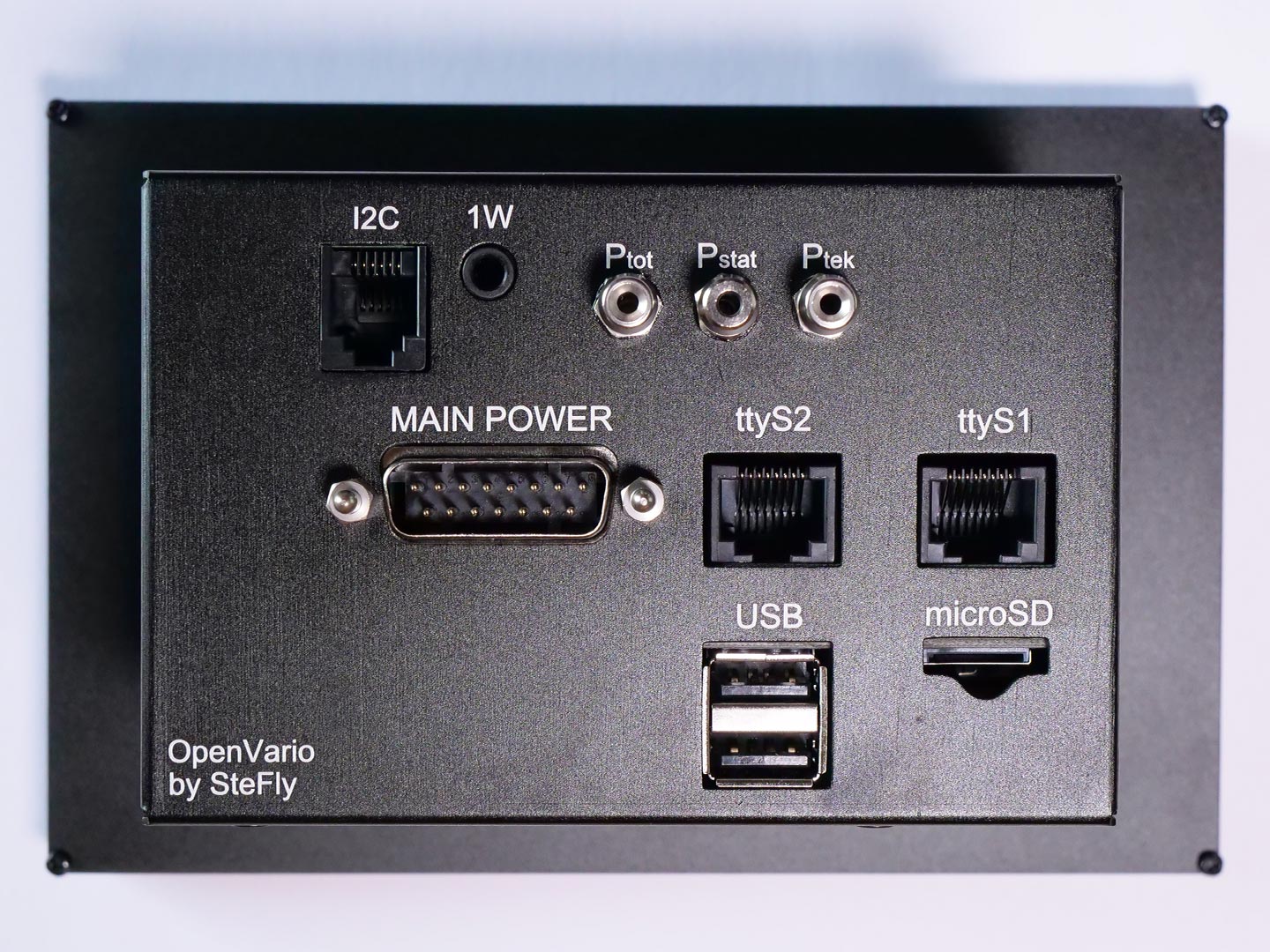

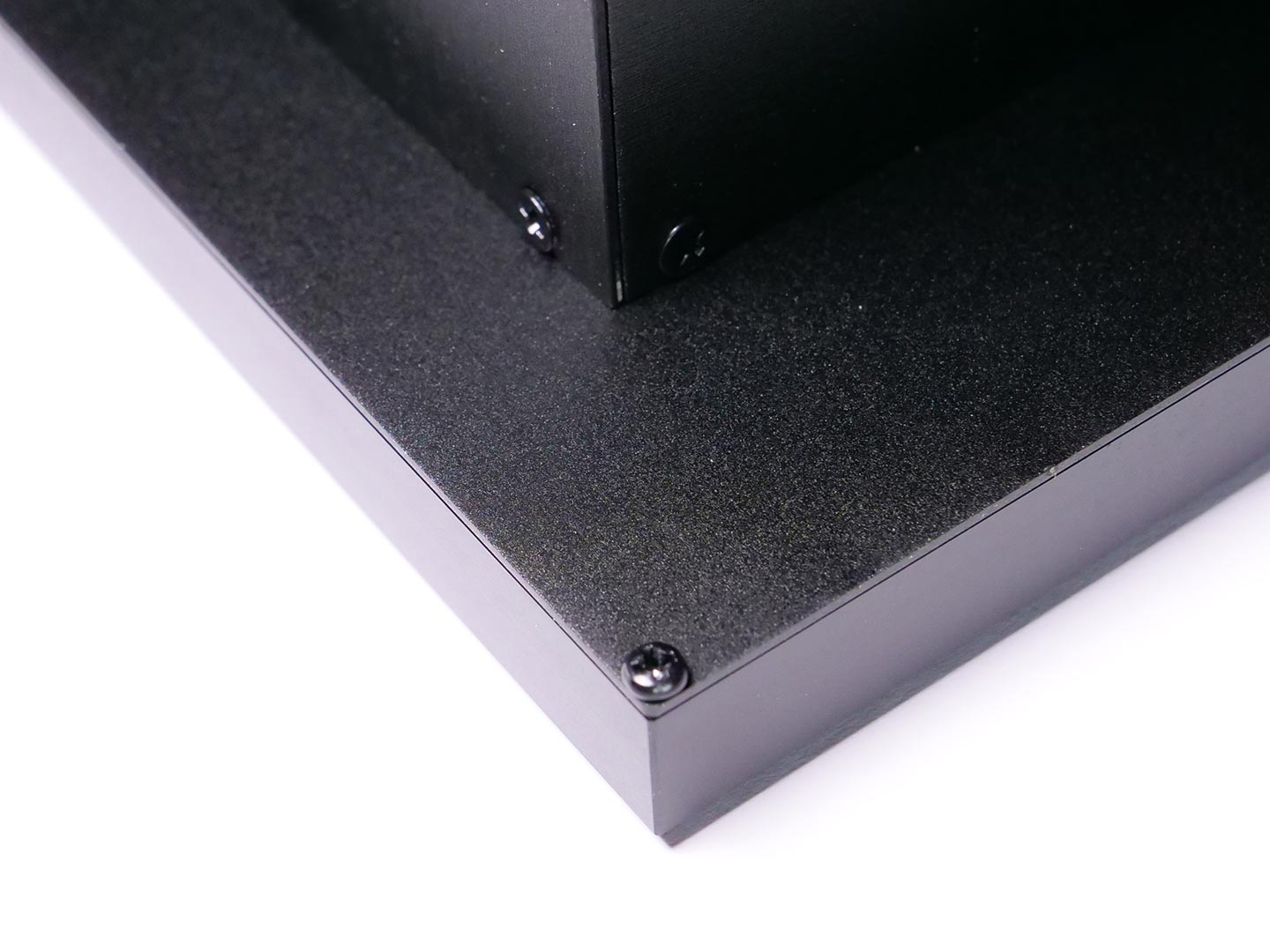

- 5,7″ oder 7″ Gehäuse mit Rahmen

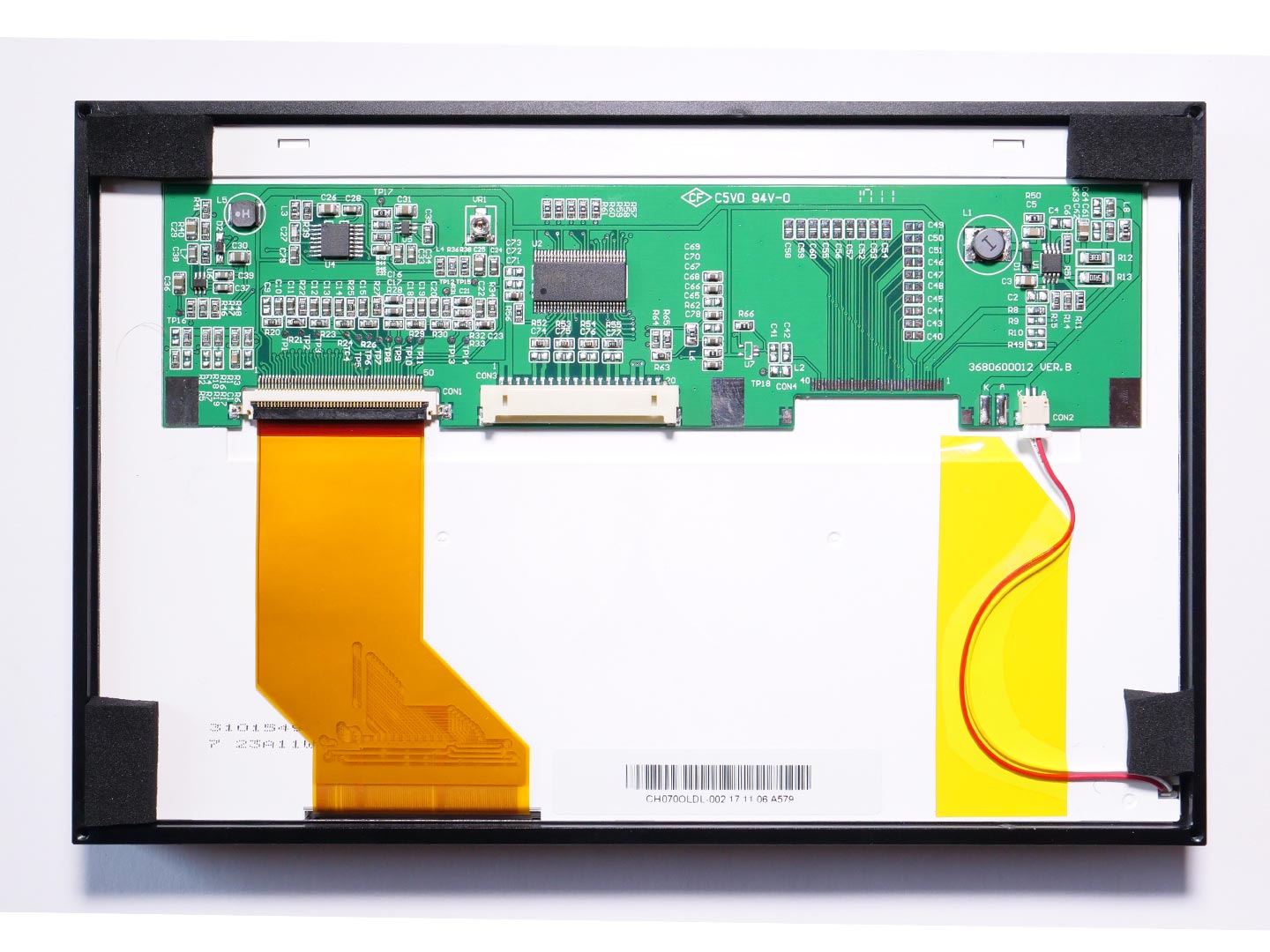

- 5,7″ oder 7″ Display

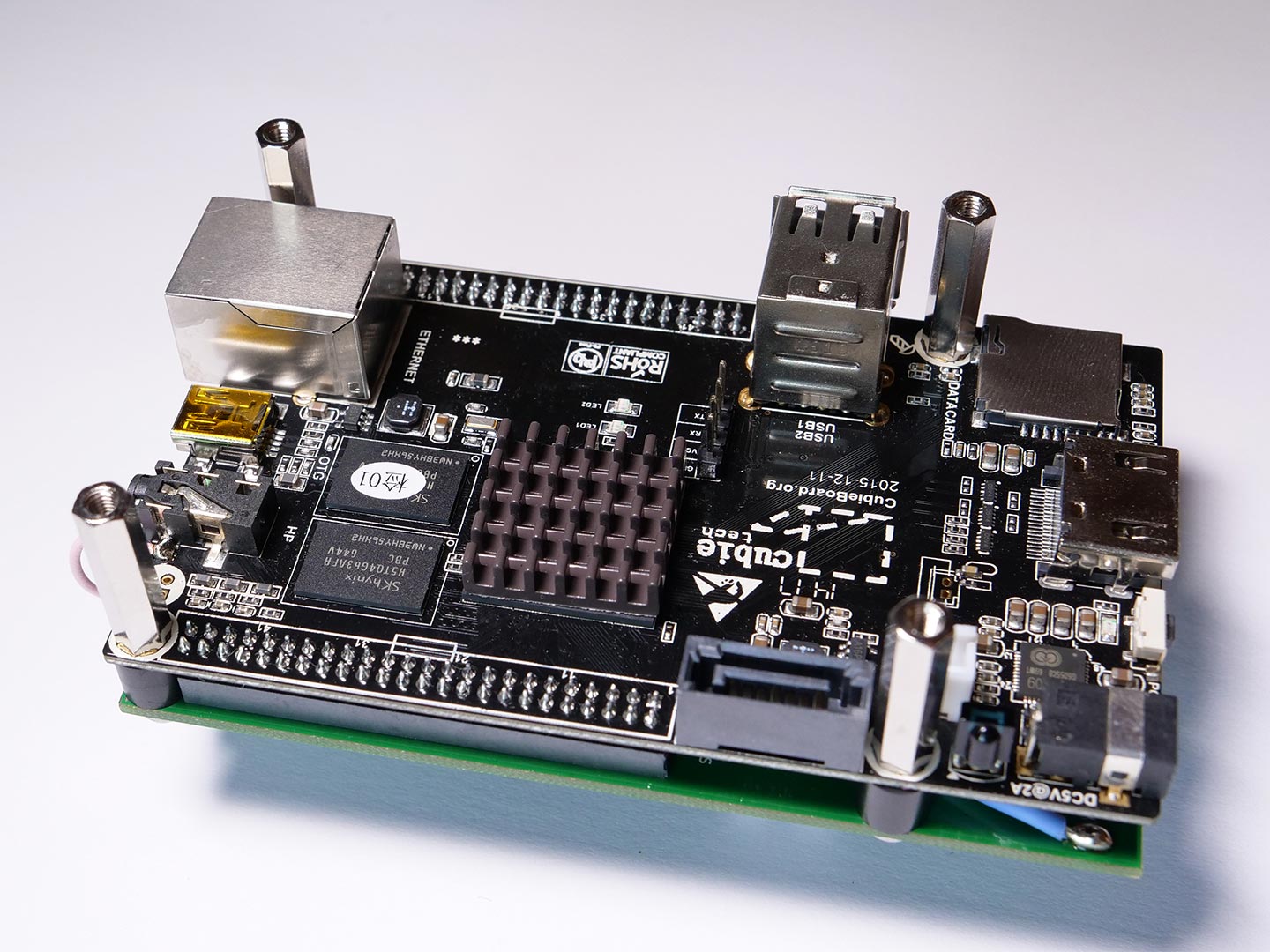

- Adapterboard mit Cubieboard2

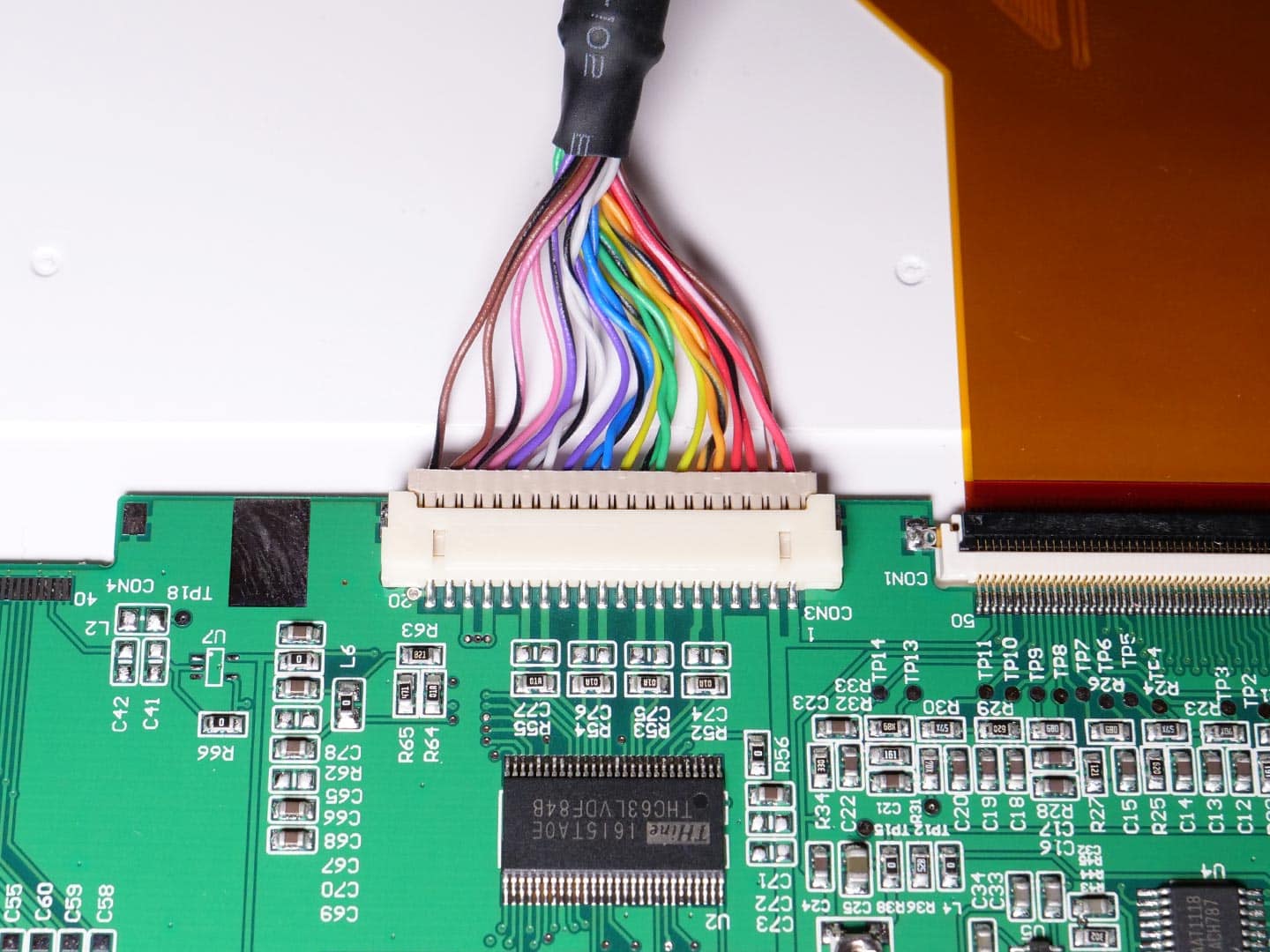

- LVDS Kabel

- Sensorboard Verbindungskabel

- 4 Gb MicroSD Karte

- Schrauben und Kleinteile

- D-Sub 15 Stecker mit Gehäuse

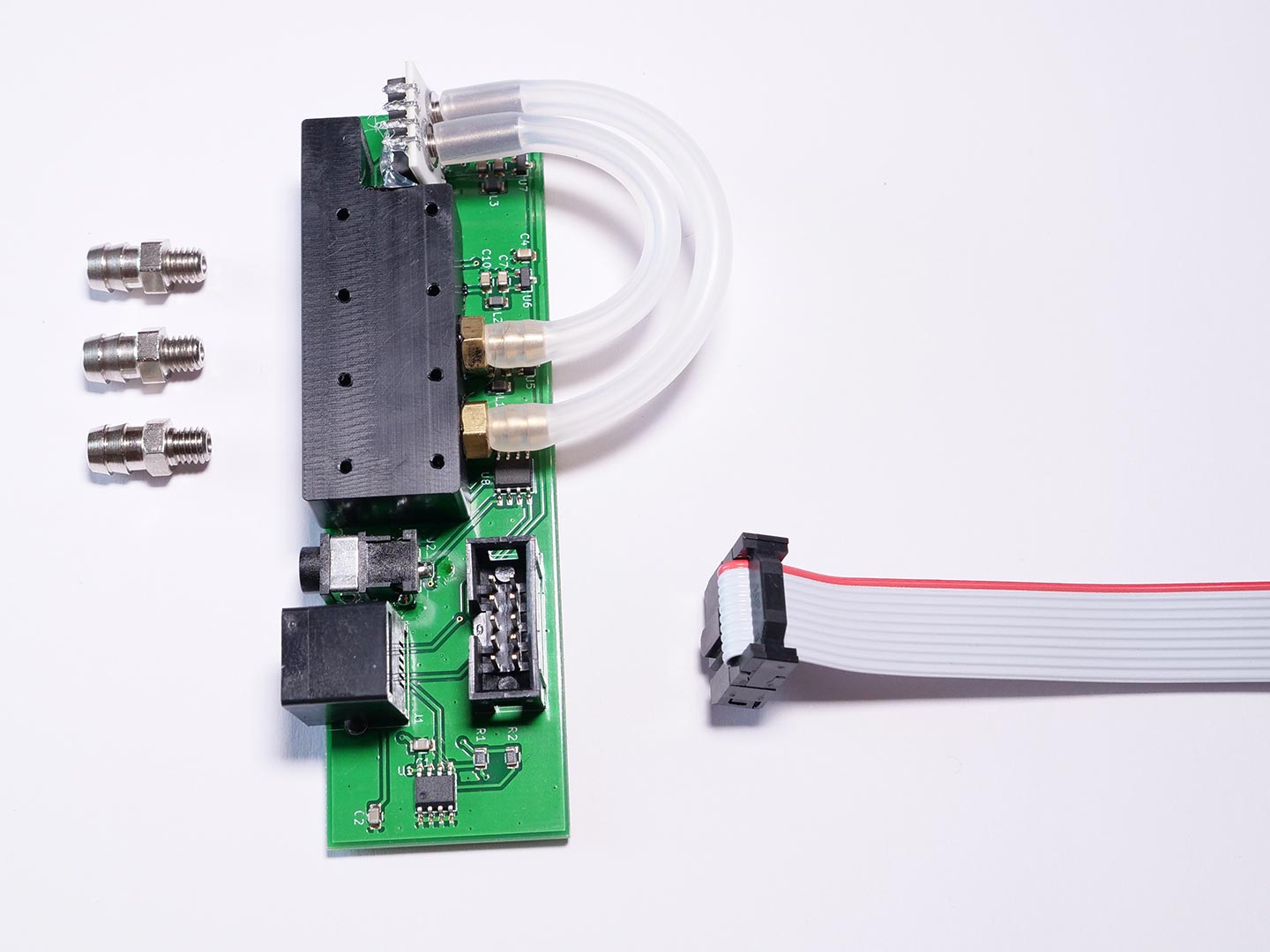

Das Sensorboard ist optional und nicht im Lieferumfang des OpenVarios enthalten. An das OpenVario kann stattdessen auch die LARUS Segelflugsensoreinheit angeschlossen werden, das ein High-End Variometer für den engagierten Streckenflugpiloten sowie Echtzeitwind-Berechnung bietet.

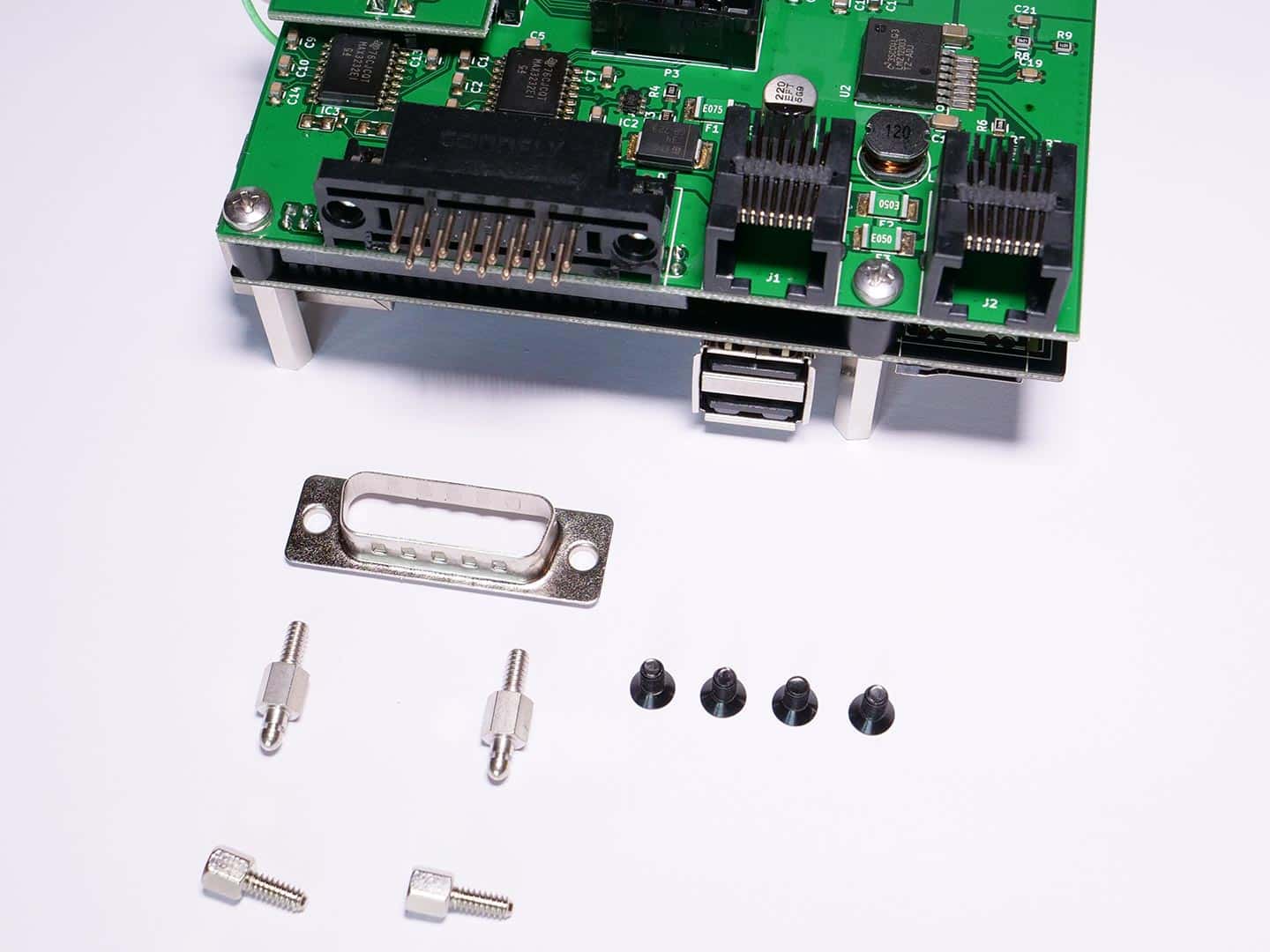

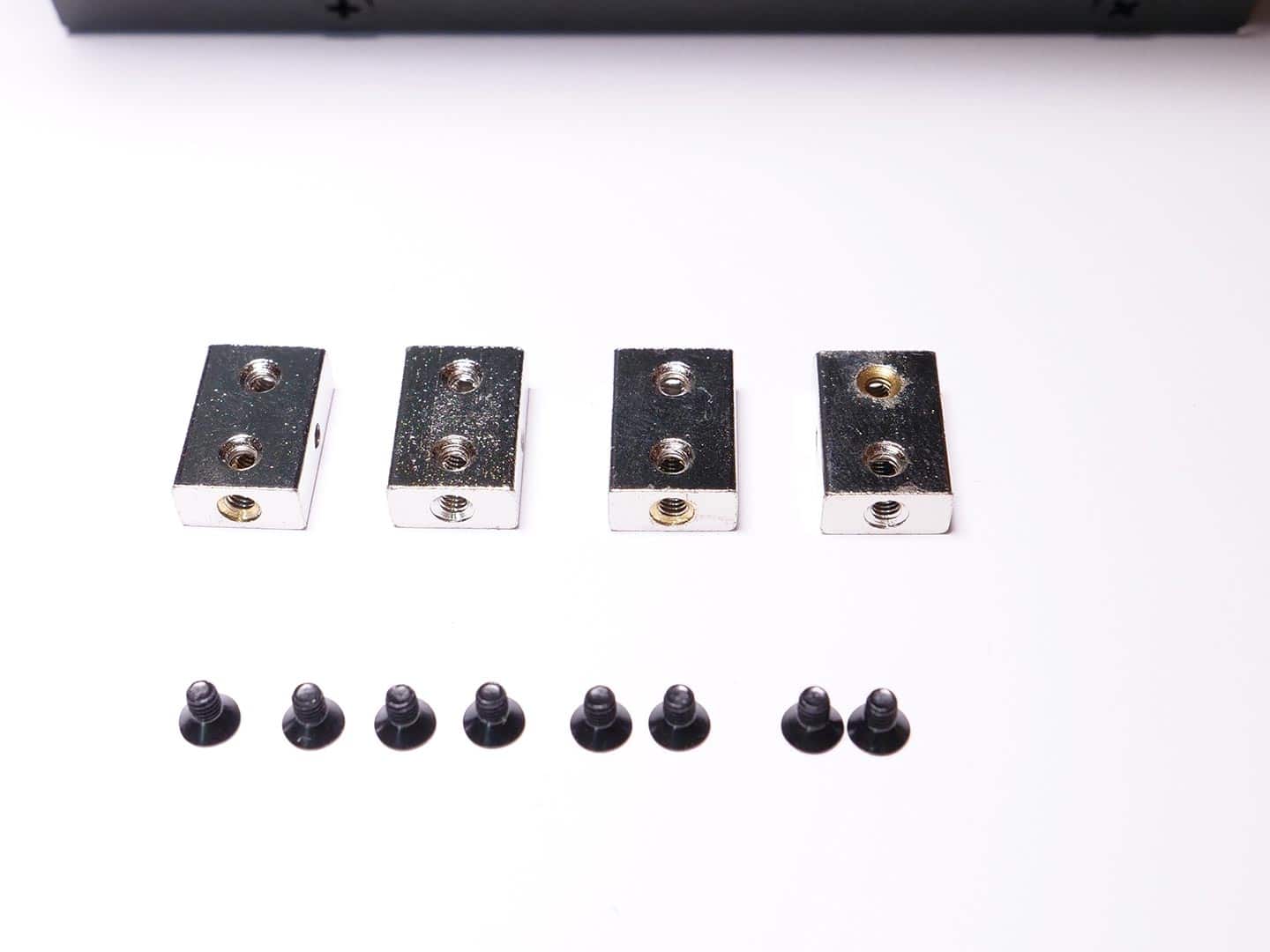

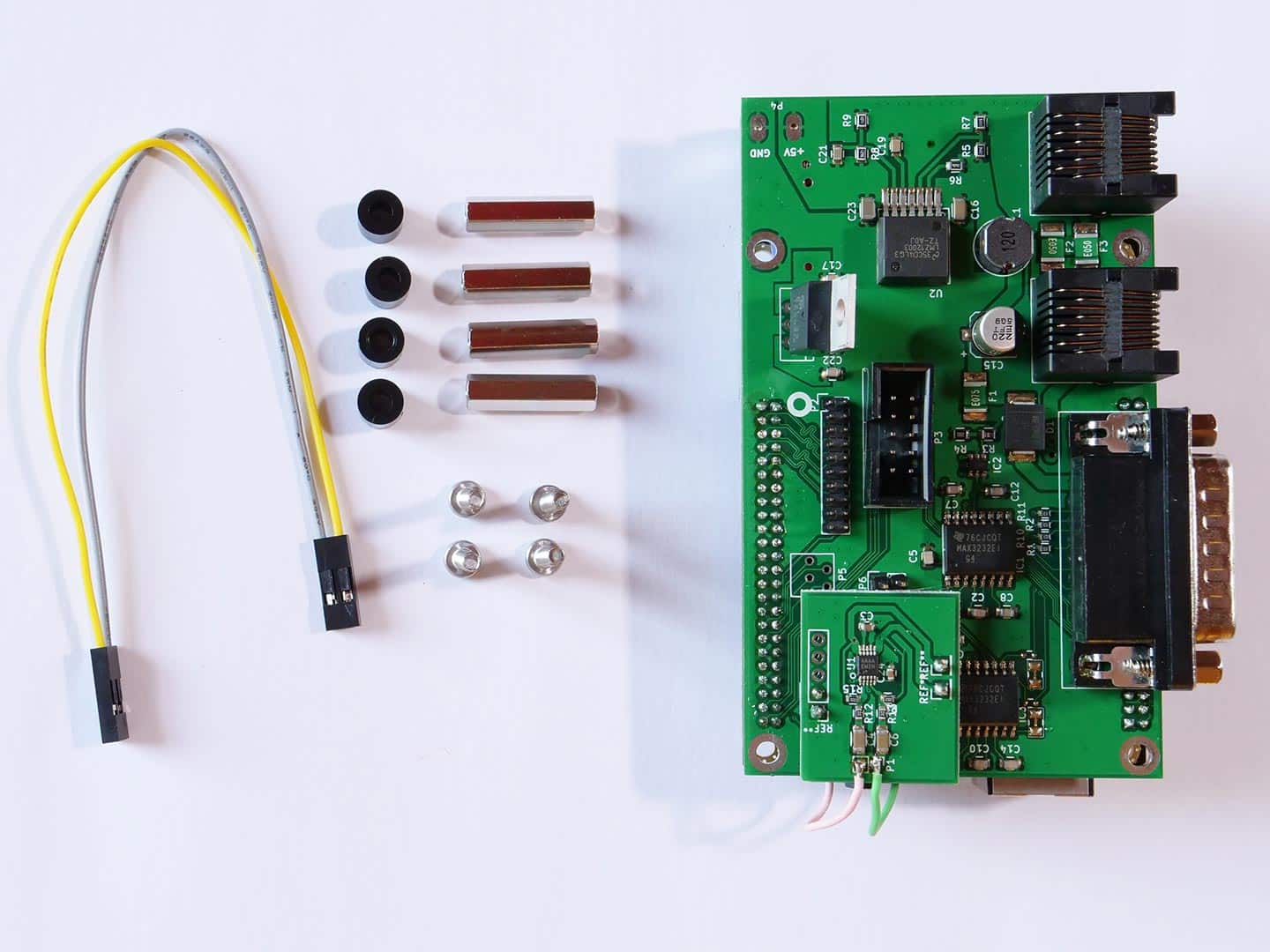

Kleinteile im Detail

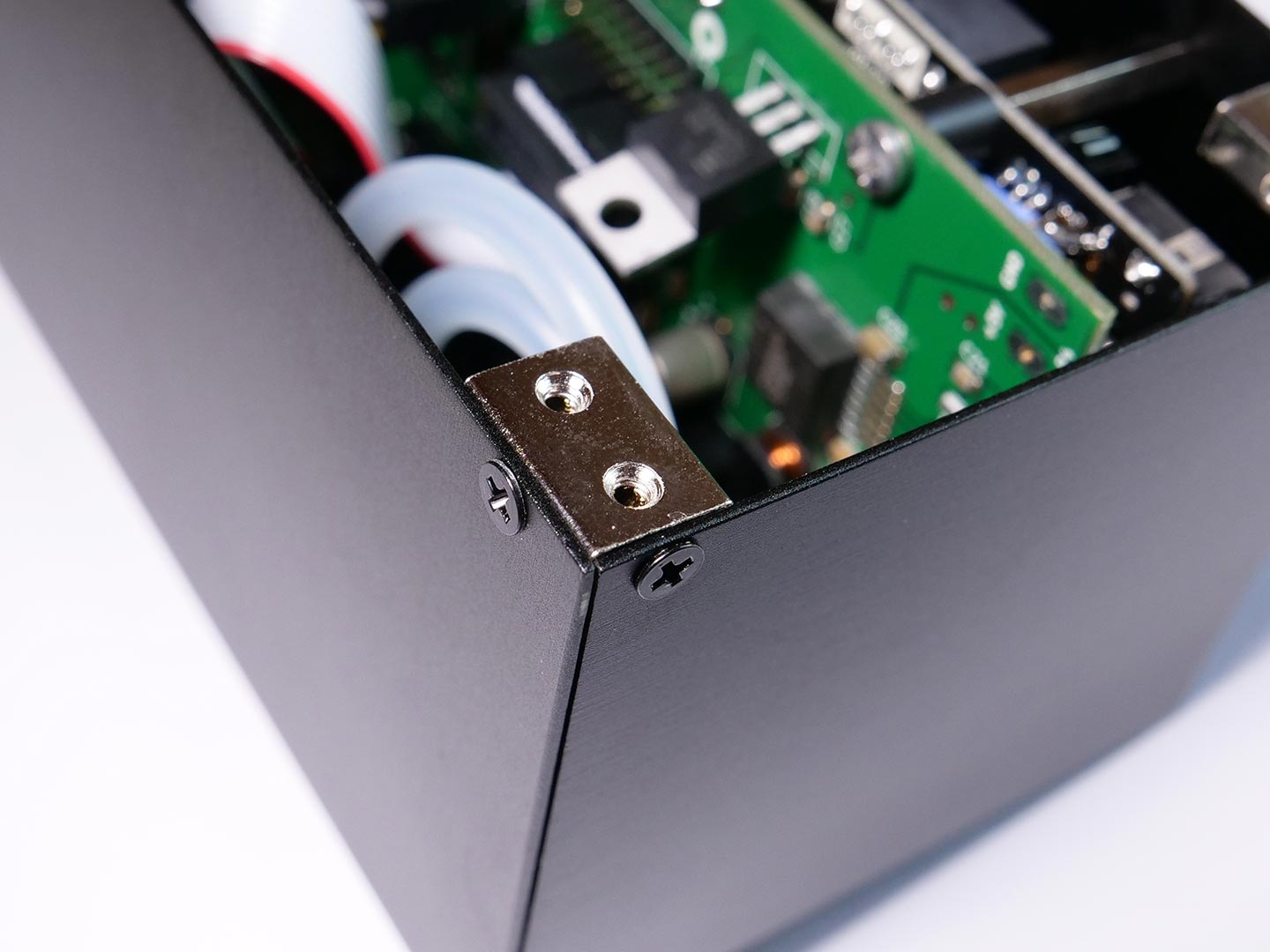

- 4 x Eckverbindungsklötze mit M2.5 Gewinde

- 4 x Kunststoff-Abstandshalter

- 4 x M3 Distanzbolzen

- 4 x lange M3 Schrauben

- 4 x schwarze M3 Senkkopfschrauben

- 12 x schwarze M2.5 Senkkopfschrauben

- 4 x schwarze M2.5 Linsenkopfschrauben

- 4 x schwarze M2 Linsenkopfschrauben

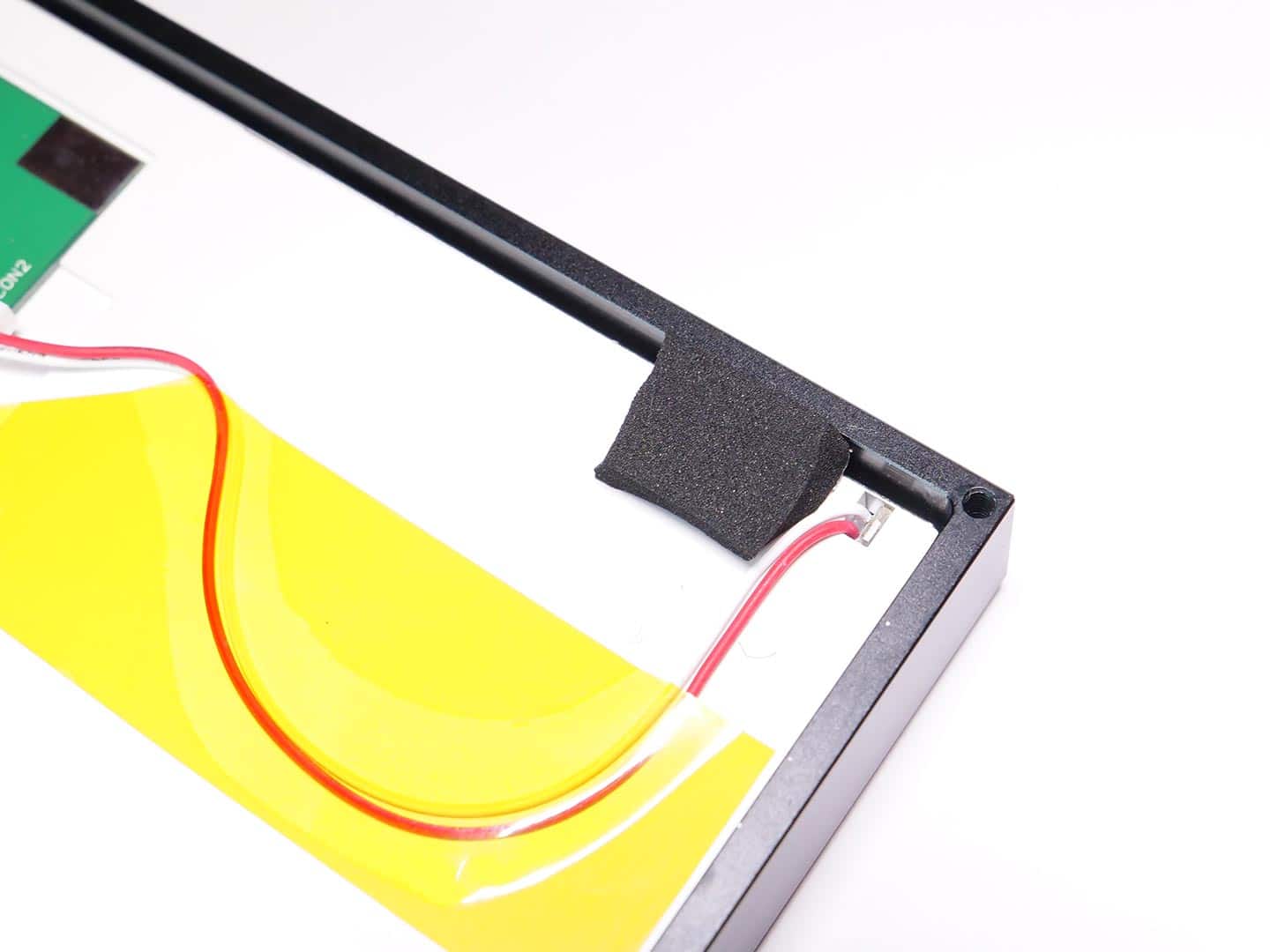

- 1 x Schaumstoff

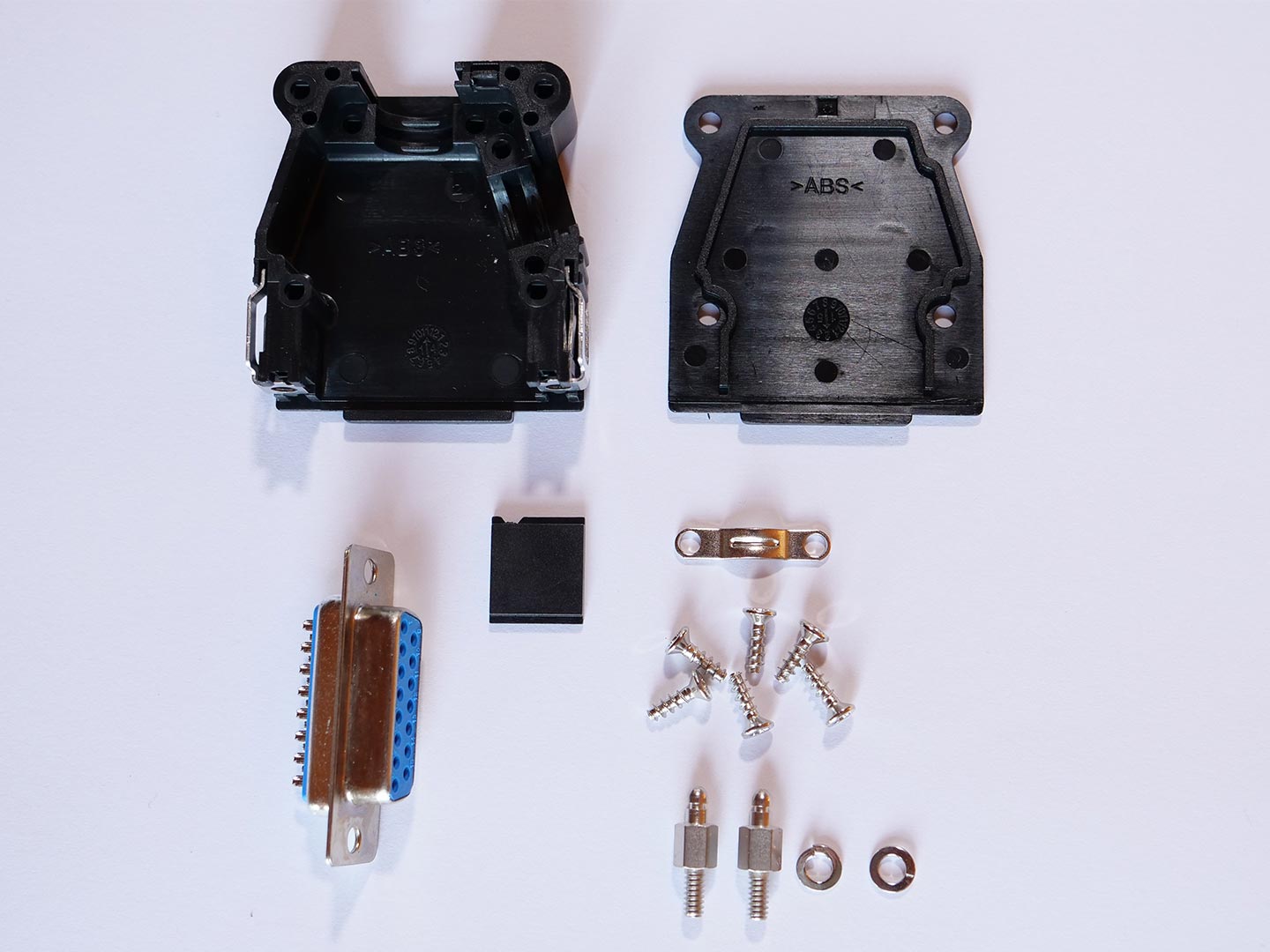

D-Sub Stecker mit Gehäuse

- D-Sub Gehäuse

- D-Sub 15 Steckerbuchse

- 6 x Schrauben

- Zugentlastungsbügel

- 2 x quick lock – Bolzen

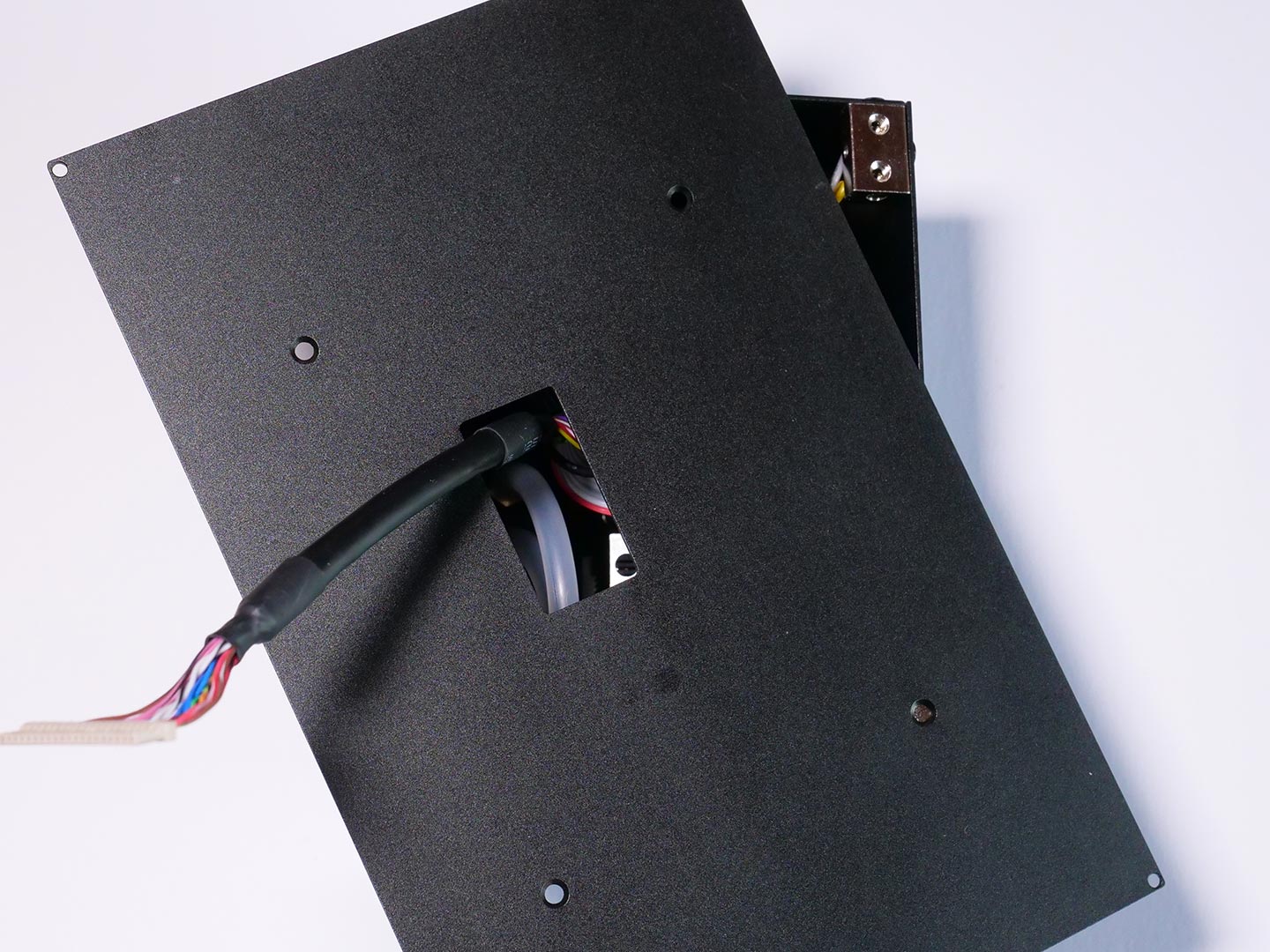

Schritt 1: Verbinden von Adapterboard & Cubieboard

Benötigte Teile:

- 4 x lange M3 Schrauben

- 4 x Kunststoff-Abstandshalter

- Adapterboard mit Cubieboard

- 4 x M3 Distanzbolzen

Bitte beachten: Schraubensicherung (z.B. Loctite®) ist nicht notwendig. Falls eine Schraubensicherung zum Einsatz kommen soll dann verwende bitte nur Versionen mit niedriger Festigkeit (z.B. Loctite® 221). Ansonsten wird eine spätere eventuelle Demontage deutlich erschwert!

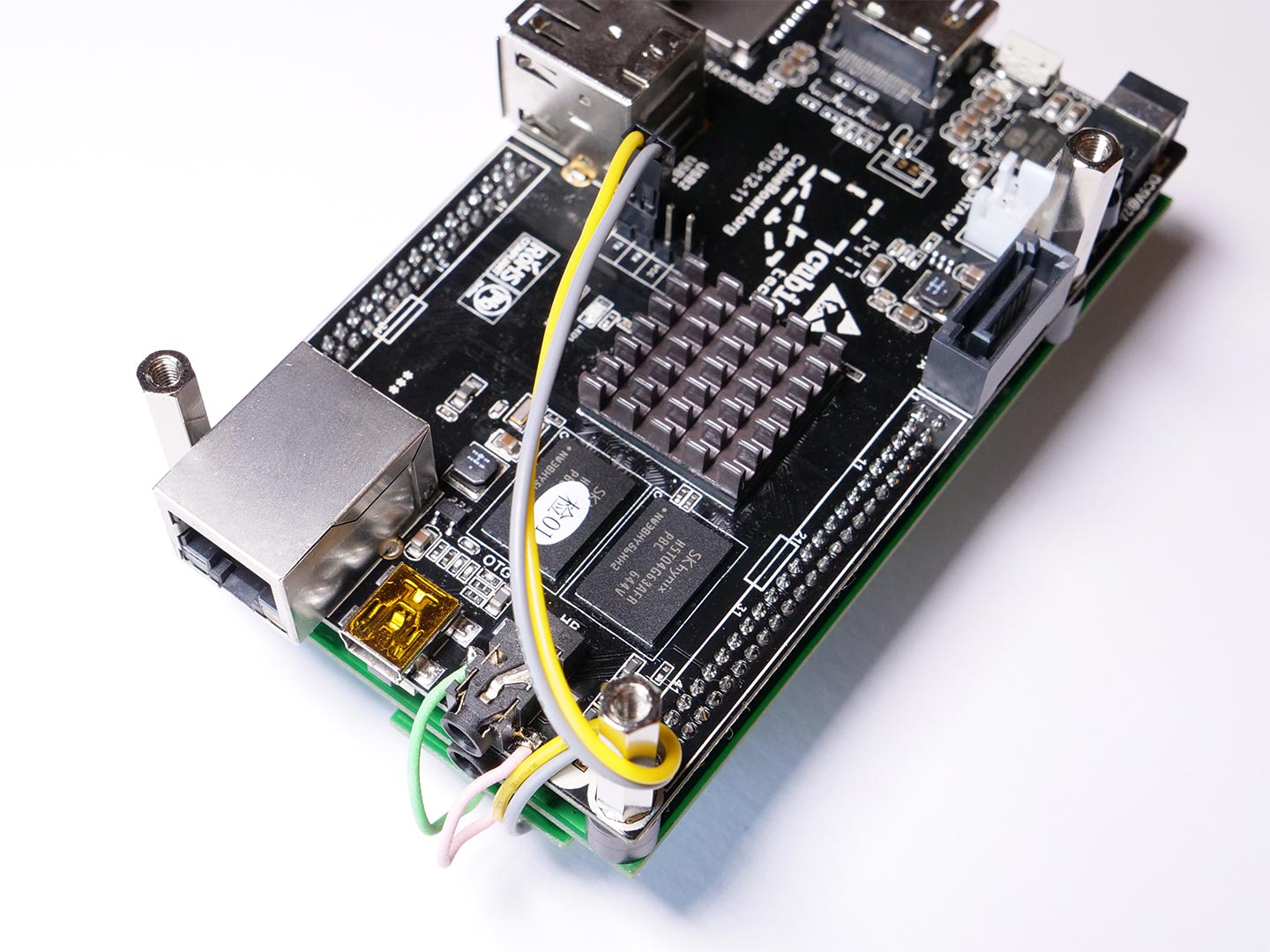

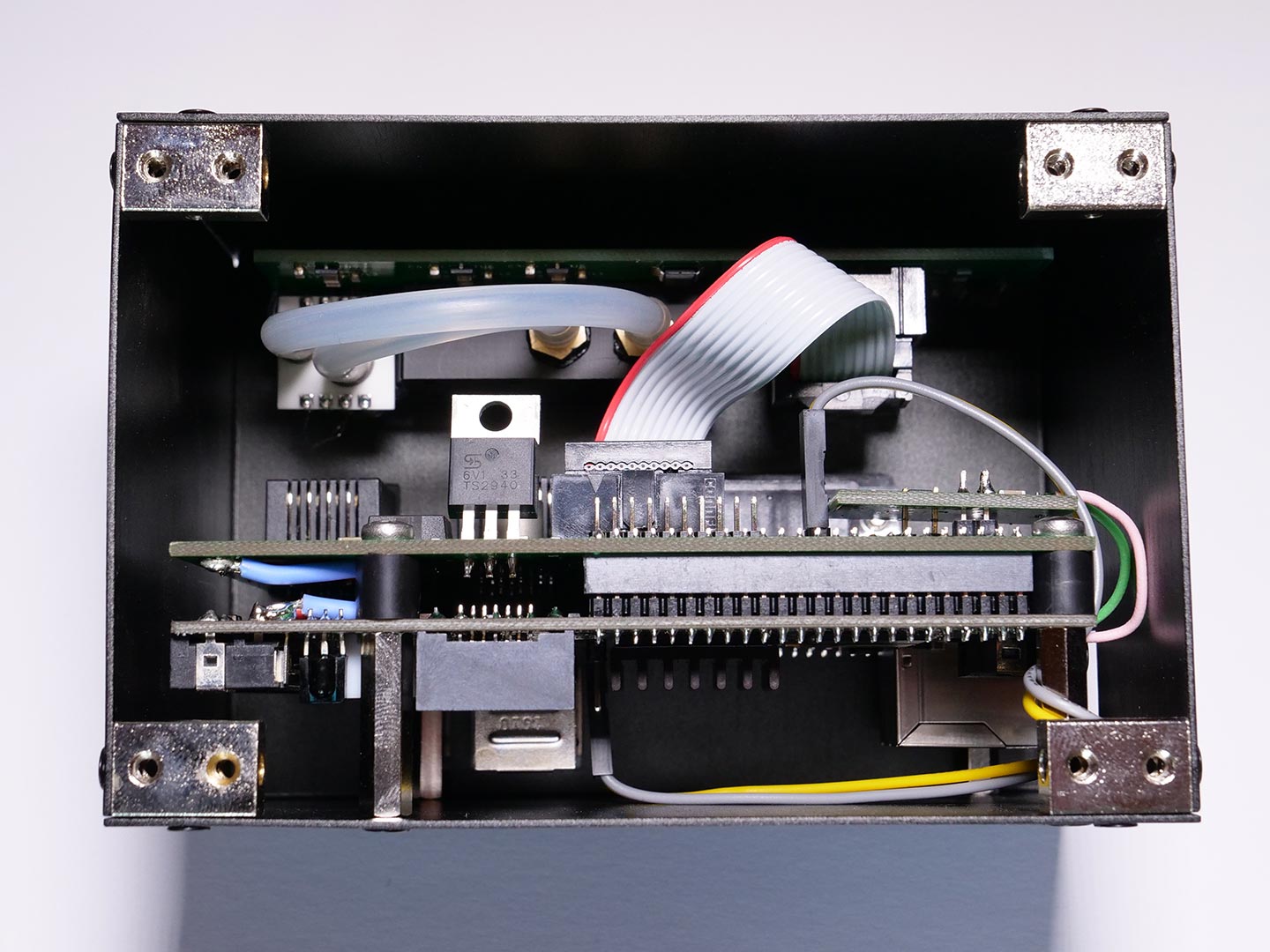

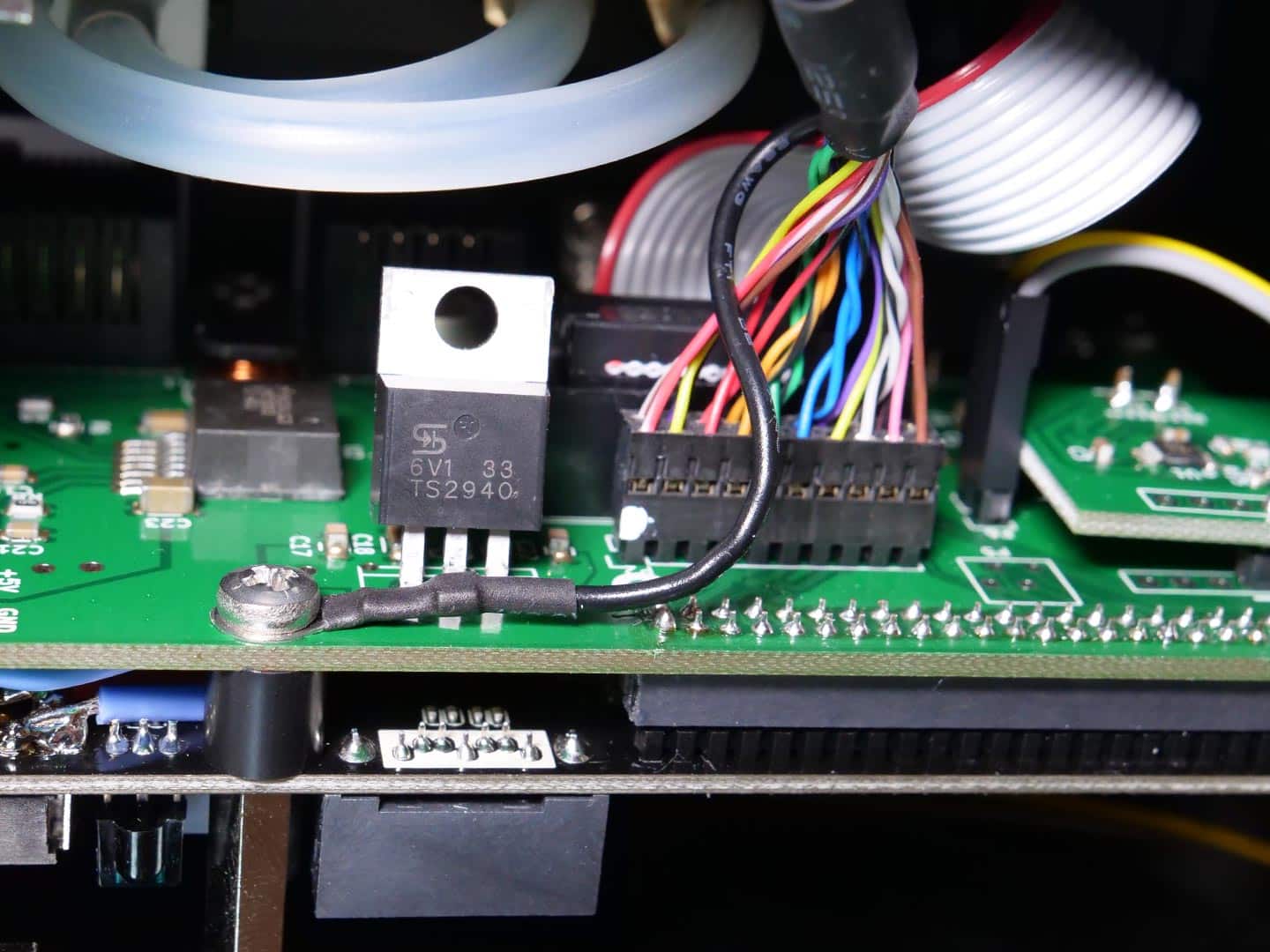

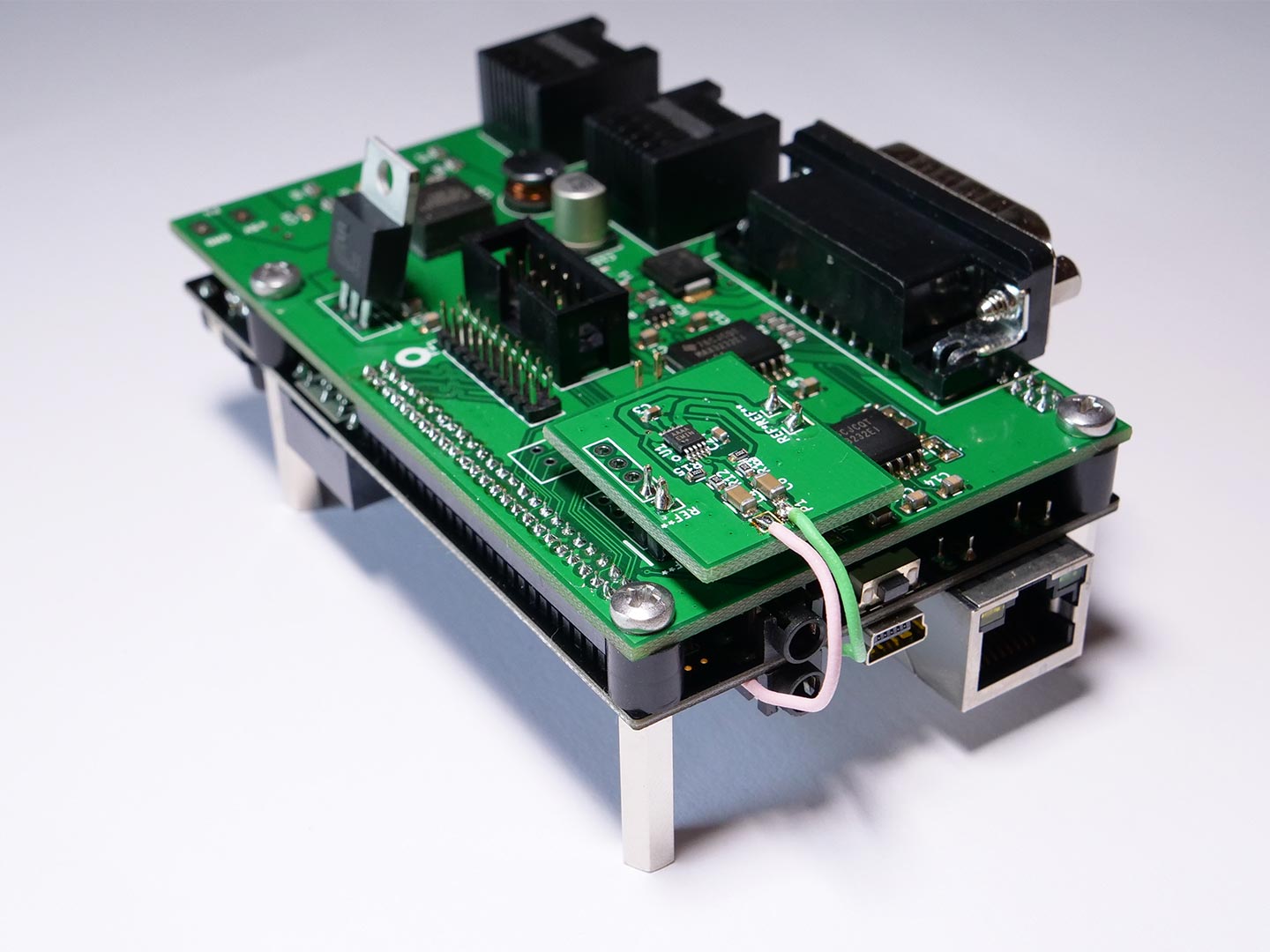

Schritt 1.1: Verbinden von Adapterboard & Cubieboard

Hinweis: Bitte beachte gleichzeitig Schritt 6: Es ist sinnvoll bereits jetzt den Ringkontakt für die Abschirmung des Displaykabels an das Adapterborad zu schrauben.

Verbinde Adapterboard (grün) und Cubieboard (schwarz) wie im Bild gezeigt. Drücke bitte die beiden Bauteile bitte nur im Bereich der beiden Steckerleisten zusammen. Insbesondere das dünne Cubieboard reagiert auf Biegung empfindlich!

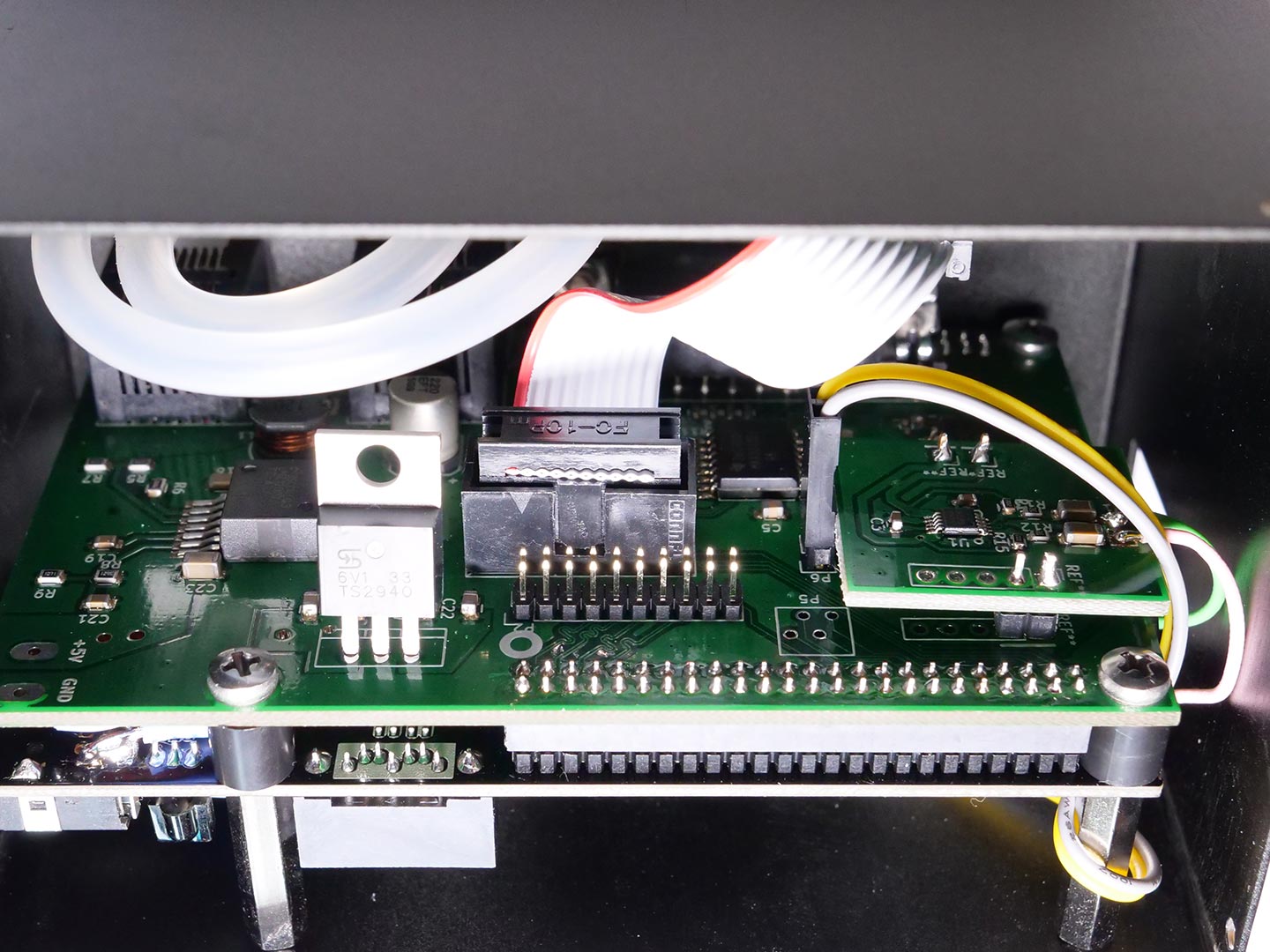

Step 1.2: Verbinden von Adapterboard & Cubieboard

Befestige die Distanzbolzen wie gezeigt.

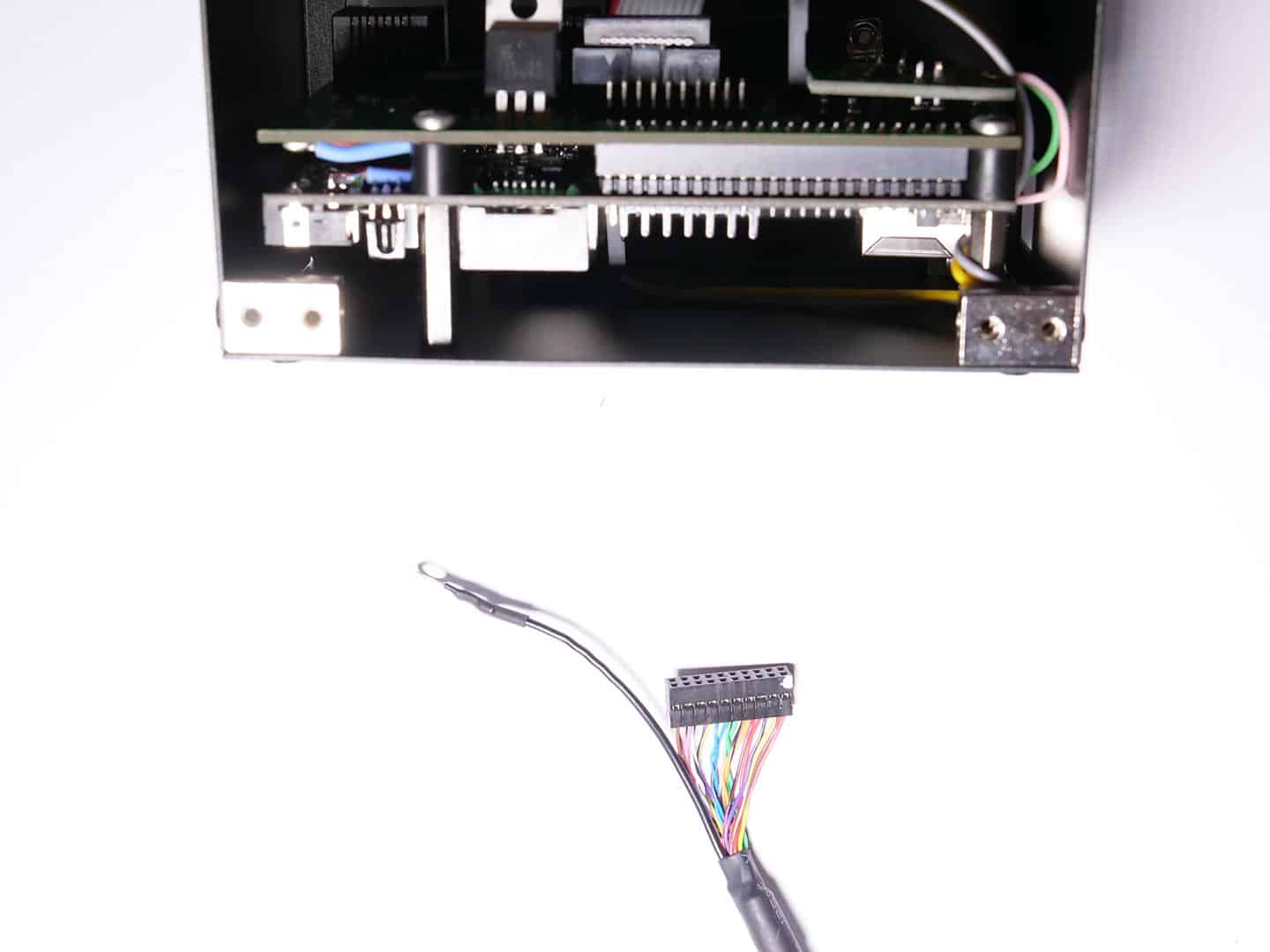

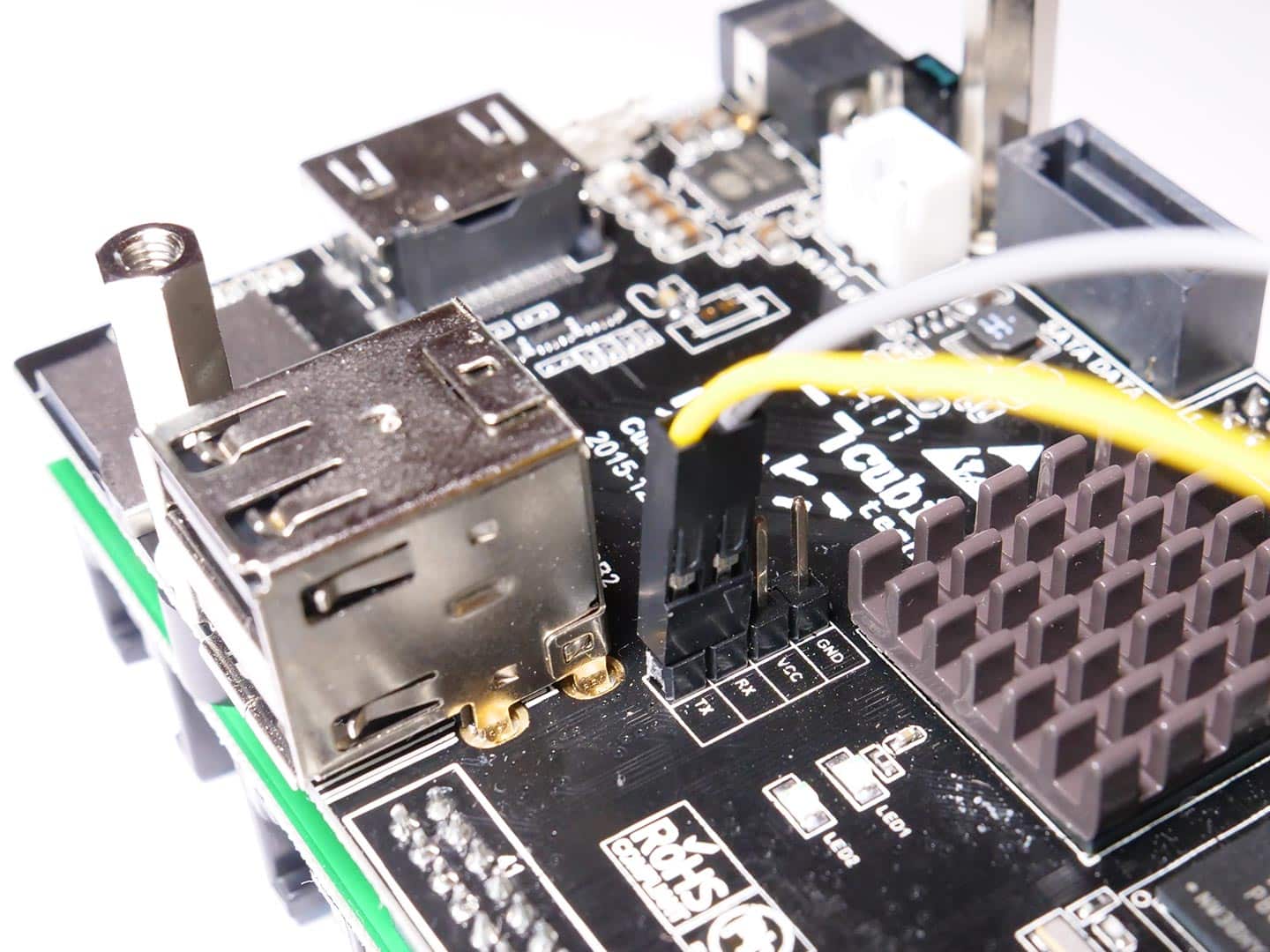

Schritt 2.1: Serielles Kabel zwischen Adapterboard & Cubieboard

Bitte beachten: Die Schritte 2.1 – 2.3 können übersprungen werden. Serielle Kabel sind aus Vereinfachungsgründen nicht mehr Bestandteil des Bausatzes.

Parts required:

- Adapterboard & Cubieboard

- 2 pin serial cable

Now you can attache the 2 pin serial cable between the Adapterboard & Cubieboard.

The Cubieboard has a pinheader with 4 pins, but we only use the RX and TX pin. Attache the cable to the RX and TX pin.

If you don´t install the serial cable, you still have 3 serial ports on the OpenVario for external devices. And at the moment, ttyS0 (UART 1) is only configured for debugging purpose.